It stands to reason—the more complex an enterprise’s operations, the more intricate the facility that must house it. Designing heavily-engineered facilities, such as ultra-modern manufacturing plants and high-tech testing labs, demands significantly more planning than simpler structures like offices or warehouses. However, with a keen understanding of the unique challenges these facilities present, it is possible to design spaces that are flexible, functional, and sustainable.

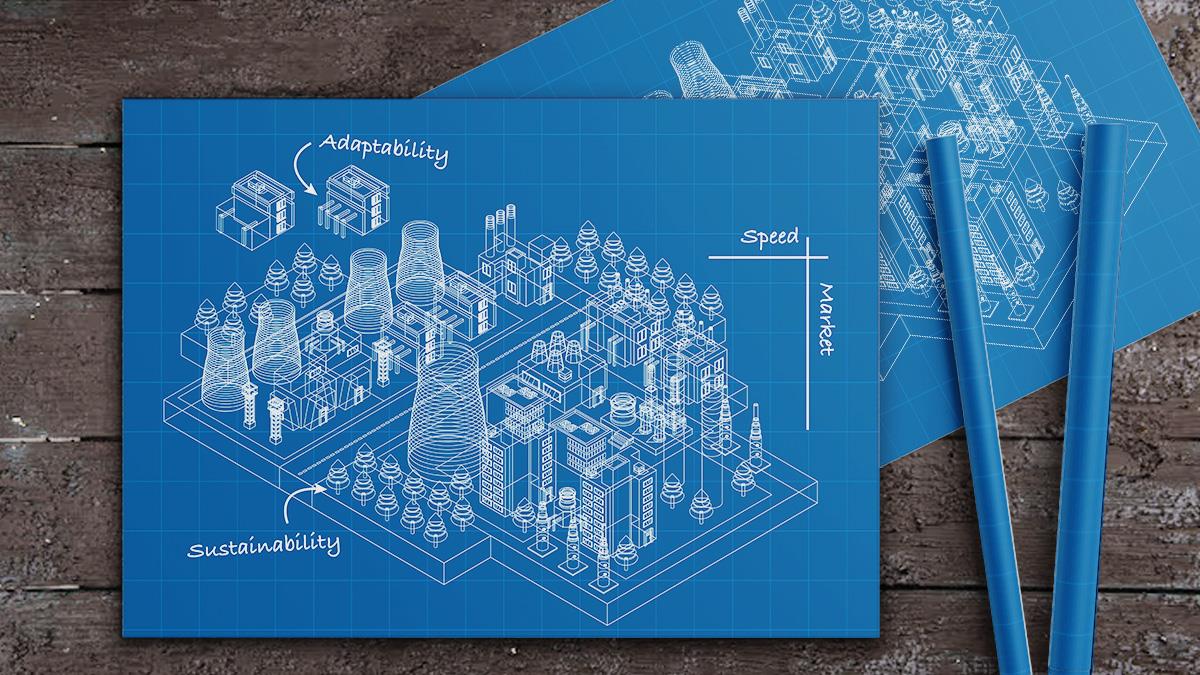

Even for a domestic facility serving a regional market, the design and construction of a heavily-engineered facility is a global and highly collaborative endeavor, dependent on dynamic supply chains in an ever-changing environment. As with any infrastructure investment, success hinges on moving from initial funding to revenue generation as quickly as possible. Demand for these types of structures is growing. Owners and stakeholders can position themselves more competitively by understanding best practices and lessons learned. Here are several key considerations.

Bringing the Best Together

The first step in developing a heavily-engineered facility is assembling a team experienced in the unique aspects of such structures. Although this may vary depending on the project delivery method chosen, the team will most likely be led by a lead designer and a general contractor. They will be supported by subconsultants and subcontractors covering all aspects of the project’s development, alongside other stakeholders providing specialized expertise.

Regardless of site location, the team will likely include members from around the world, particularly in the procurement of materials, equipment, and technology. Maximizing collaboration within a cross-cultural team can be challenging, but proven techniques exist to help stakeholders function as a cohesive unit aligned with the owner’s goals.

Language barriers may slow decision-making, but effective use of graphical information and visual displays can greatly aid communication. To better understand one another, even when different languages are spoken, most industries utilize standard graphical symbols and diagrams that are universally understood by professionals worldwide.

Using graphical and visual tools effectively helps overcome language gaps, but attention must also be paid to cultural barriers. Understanding global business practices—including acceptable behaviors and expected customs—is essential to building trust and fostering collaboration.

Building-In Sustainability

The need to integrate sustainable features into facilities is being driven by ecological, economic, and regulatory factors. While some elements may be required by building codes or government mandates, others should be guided by the unique manufacturing processes, equipment maintenance needs, and even evolving market dynamics over the building’s lifecycle. The overarching goal is to reduce operational costs, minimize energy consumption, and achieve long-term efficiency.

Prioritizing Speed to Market

As noted, demand for heavily-engineered facilities is increasing, making rapid planning, design, and construction more important than ever. However, this urgency is challenged by lingering effects of the COVID-19 pandemic, which continue to disrupt supply lines. Additionally, geopolitical factors may delay procurement of equipment and materials.

A project team with market-specific experience will know how to navigate these obstacles. They will anticipate hard-to-source equipment and advise early procurement, if necessary. If preferred materials pose a risk of delaying the schedule or inflating costs, the team can recommend viable alternatives.

In addition to securing physical resources, an experienced team ensures that the necessary human resources are available. The construction industry is currently grappling with a shortage of skilled labor. Knowledge of the regional workforce and strong relationships with trade unions enable seasoned contractors to respond effectively.

Labor shortages are also being addressed through modular construction. By manufacturing building components off-site, the need for on-site labor is significantly reduced. Modular components are designed for quick assembly and require less technical expertise than traditional methods.

Modular design offers additional advantages. It can streamline construction phases and reduce costs through economies of scale. Perhaps most importantly, it enhances flexibility. Many modular components can be disassembled and reconfigured, enabling future refurbishments and easier equipment replacements.

Adaptability in Execution

Flexibility is essential not just in building design but also in project execution. In a complex project, disruptions should be anticipated—from changes in technology to material shortages. While such challenges may not be fully predictable, their impact can be minimized by fostering a team mindset centered on adaptability.

Combining trades and construction strategies in a flexible first-pass integration plan offers needed versatility. Quality control and assurance procedures—including internal and third-party reviews—keep the project aligned with goals. Committing to specific project completion percentages and milestones fosters early buy-in and builds confidence.

Robust communication plans ensure that updates are quickly shared across the team. Regular updates to designs and construction documents help maintain a current understanding of project status. A timely response to disruptions is far more effective when all stakeholders are informed and aligned.

Beyond processes and protocols, the human element is key to high-performance teamwork. Building trust and cohesion through personal relationships enhances collaboration. Social activities outside work hours can be especially effective in overcoming cultural barriers and uniting the team.

Being a Good Neighbor

Large manufacturing facilities are highly valued by municipalities for the jobs and revenue they bring. However, they can also strain public resources. Such facilities demand substantial water and electricity, may require sewer system upgrades, and can necessitate roadway improvements due to increased traffic.

While these concerns are typically addressed during site selection, they can still affect project outcomes. It is vital to engage with the local community proactively. Early public buy-in and ongoing responsiveness to community concerns can greatly ease the project’s path forward.

Conclusion

As the world grows increasingly high-tech, the products manufacturers create become more complex. Designing and building facilities that can support this complexity presents new and evolving challenges. Successfully managing these projects requires a multicultural team capable of adapting to change and developing sustainable, high-performance buildings.

Attention to detail, rapid execution, and effective collaboration are now essential. Fortunately, proven strategies and tools exist to meet these demands. We hope these practical insights into designing facilities for complex manufacturing have provided just that.