When it comes to predictive maintenance, few voices speak with the grounded clarity of Dylan Heit, Reliability Manager at Domtar Meadow Lake Mill. With more than 15 years of focused reliability and vibration analysis under his belt, Dylan has long believed in the power of condition-based maintenance — but it wasn’t until the team incorporated ultrasound, particularly SDT’s ON-GUARD continuous monitoring system, that they began to truly transform the way they approach machinery lubrication.

Moving Beyond Time-Based Lubrication

For Domtar, like many industrial operations, lubrication had traditionally followed a rigid time-based schedule — greasing bearings on fixed intervals rather than addressing the equipment’s actual condition. But Dylan and his team began to notice a gap. High-frequency data from their vibration monitoring kept indicating a lubrication fault condition was present, even though the lubrication team was following a strict time-based lubrication schedule.

That’s when ultrasound entered the picture. Dylan’s team adopted SDT’s LUBExpert — a route-based ultrasound device specifically designed to guide precision lubrication tasks. The tool provides real-time feedback, measuring decibel levels and calculating exactly how much grease is needed.

Unlike traditional greasing methods, LUBExpert doesn’t just tell you when to lubricate — it ensures the right type of grease and amount of grease is applied every time. It also allows technicians to perform lubrication tasks in either “Guided” or “Free” mode. In Guided mode, the technician follows a structured, step-by-step approach to ultrasound-assisted lubrication. While Free mode provides greater flexibility, allowing technicians to adapt the lubrication process in real-time based on sensor response.

During lubrication tasks, LUBExpert captures both static and dynamic ultrasound data, with the option to also take temperature and tachometer readings. The data is then uploaded into UAS3 software for further analysis.

UAS3 Software view of ultrasound time waveform recorded during lubrication task.

The Four Condition Indicators are trendable, easy-to-interpret data points recorded during every LUBExpert guided lubrication task.

LUBExpert on screen view of the Four Condition Indicators of a lubrication task.

RMS (Root Mean Square): Averages the entire sample captured and returns a single RMS decibel value. The overall RMS is used to trend the condition of a bearing and overall friction throughout its lifecycle. This is great for detecting lubrication faults and for trending and setting alarms.

Max RMS: The highest of the sub RMSs calculated every 250ms. Compared with the RMS, it is used to find out if the signal is stable or if it varies.

Peak: The maximum instantaneous value recorded during a measurement recording. It is used primarily for impacts produced by early stages of failure in bearings, gears, and couplings.

Crest Factor: Ratio of Peak to RMS. Indicates severity of defects like bearing wear or lubrication issues. Ideal for trending the repetitive nature or severity of a defect.

From Route-Based to Always-On

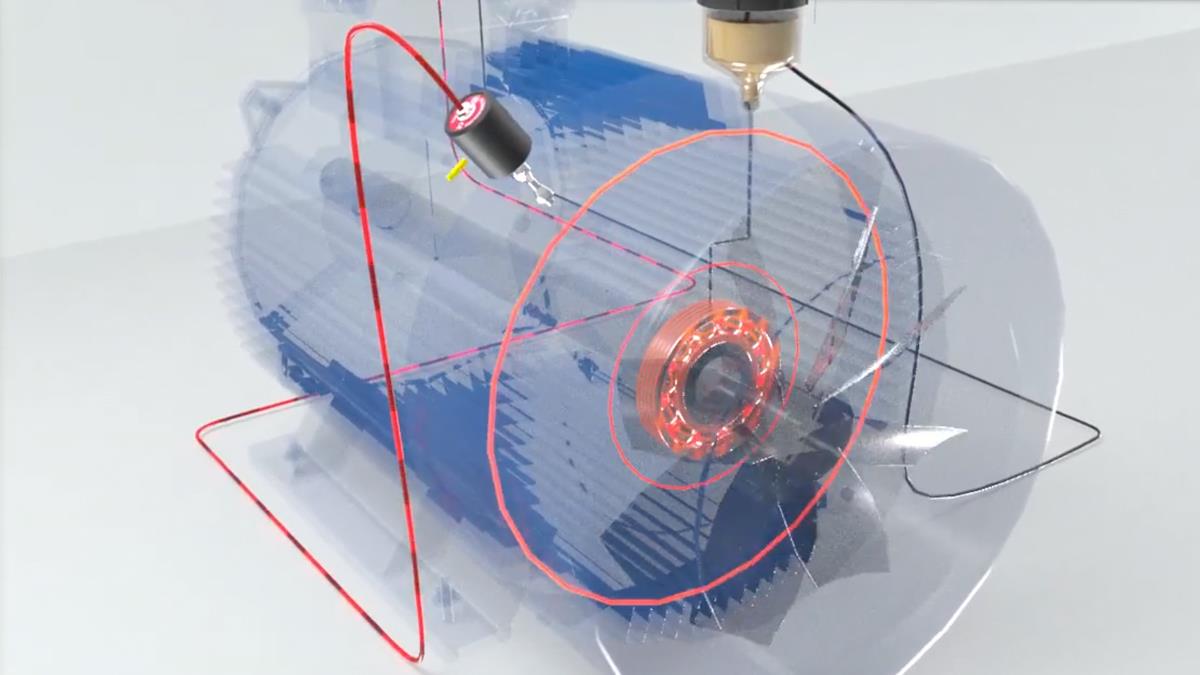

While the LUBExpert offered invaluable improvements to manual lubrication, the next leap came with the adoption of SDT’s ON-GUARD system — a fully automated, condition-based lubrication and monitoring platform. Unlike traditional ultrasound tools used in periodic inspections, ON-GUARD provides 24/7 continuous monitoring of bearing condition, temperature, and lubrication needs, and can automatically trigger grease delivery based on real-time data.

Below is a one-month trend from a bearing monitored by ON-GUARD. The red line marks the alarm threshold that triggers lubrication and the blue line is the assets friction levels measured in RMS. The green markers show each automated greasing event and the orange line indicates how much grease was injected. Together, these trends tell a complete story—how the asset behaved, how ON-GUARD responded, and how friction was brought back under control.

One month trend view of the ON-GUARD Dashboard.

Dylan was among the first to beta test ON-GUARD, applying it to one of their most demanding assets: an over-speed centrifugal fan known for its lubrication challenges.

“The ON-GUARD system gave us real-time transparency,” Dylan recalls. “Not just condition indicators and temperature trends, but automated greasing that adjusted based on the asset’s actual needs. It replaced guesswork with hard data.”

The impact was immediate. ON-GUARD revealed that the drive-end bearing required nearly twice the grease as the non-drive end — a detail the team never would have caught using conventional, time-based lubrication schedules. By eliminating under- or over-greasing, the system delivered precisely the right amount at the right time, significantly improving reliability and extending bearing life.

Building Trust Through Data

Initially, the team monitored the ON-GUARD dashboard closely — especially given the fan’s history of sensitivity. But as they gained confidence in the system’s insights and reliability, they relaxed their manual oversight, allowing ON-GUARD to do what it was designed for.

“It’s about building trust with the data,” Dylan says. “Once the system shows you how the asset responds and you’ve configured it right, you let it run. The only time you need to step in is when it alerts you to refill the grease canister or flag an anomaly.”

A Holistic Reliability Strategy

For Dylan, ultrasound isn’t just about lubrication. At Domtar Meadow Lake, it’s part of a broad and well-integrated condition monitoring program, complementing vibration analysis, thermography, oil analysis, and more.

Aside from playing a role in precision lubrication, ultrasound is equally valuable in fluid and electrical systems. It detects internal leakage or improper flow in valves, identifies failed or leaking steam traps that drive up energy costs, and pinpoints compressed air, gas, and vacuum leaks that silently drain resources. In electrical applications, airborne sensors help locate high-risk issues like corona, tracking, and arcing before they become dangerous or damaging. For new condition monitoring technicians, Dylan notes, ultrasound is often the most intuitive place to start.

“It engages another sense — hearing. You can listen to the asset, view the data visually, and build confidence. For beginners, especially with slow-speed assets, it is less intimidating and complex than the vibration technology.”

The Bottom Line

For plants considering ON-GUARD or ultrasound in general, Dylan’s advice is clear: the value is undeniable.

“Ultrasound provides significant value at a relatively low entry cost,” he says. “And the ON-GUARD system, in particular, gives you continuous insight, automated action, and the peace of mind that you’re treating your assets right — all the time.”

Whether you’re running lean with fewer maintenance techs or looking to sharpen the precision of your lubrication practices, ON-GUARD helps eliminate the guesswork, reduce downtime, and extend equipment life. For Dylan and his team at Meadow Lake, it’s become a core part of how they do business — and a reminder that condition monitoring isn’t just about identifying faults, but clearly understanding machine health and preventing them altogether.

The information provided herein is for general informational purposes only and is not intended as technical, engineering, safety, or compliance advice. Domtar is a customer of SDT, and makes no guarantees regarding the performance, safety, or effectiveness of the products mentioned. Use of any product or service should be undertaken at your own discretion and risk. Individual results may vary.

Smart Ultrasound Condition-Based Lubrication

The LUBExpert ON-GUARD blends automation with precision, reliability, simplicity, and safety. It ensures long-lasting, trouble-free operation of your rotating assets by maintaining optimal lubrication, all through innovative ultrasound measurement technology.