"The Global Vibration Sensor Market Size was valued at USD 4.29 billion in 2023 and is expected to reach USD 8.19 billion by 2032, growing at a CAGR of 7.5% over the forecast period 2024–2032."

"The market for vibration sensors has seen rapid growth and is poised for continued expansion due to their critical role in industries such as automotive, aerospace, healthcare, consumer electronics, and manufacturing. Accelerometers, or vibration sensors, are essential for monitoring vibrations, shocks, and accelerations, ensuring machinery health and structural integrity. With the rise of digital twins and predictive maintenance, demand for vibration sensors is surging, enabling real-time monitoring, early fault detection, and optimized performance."

Introduction

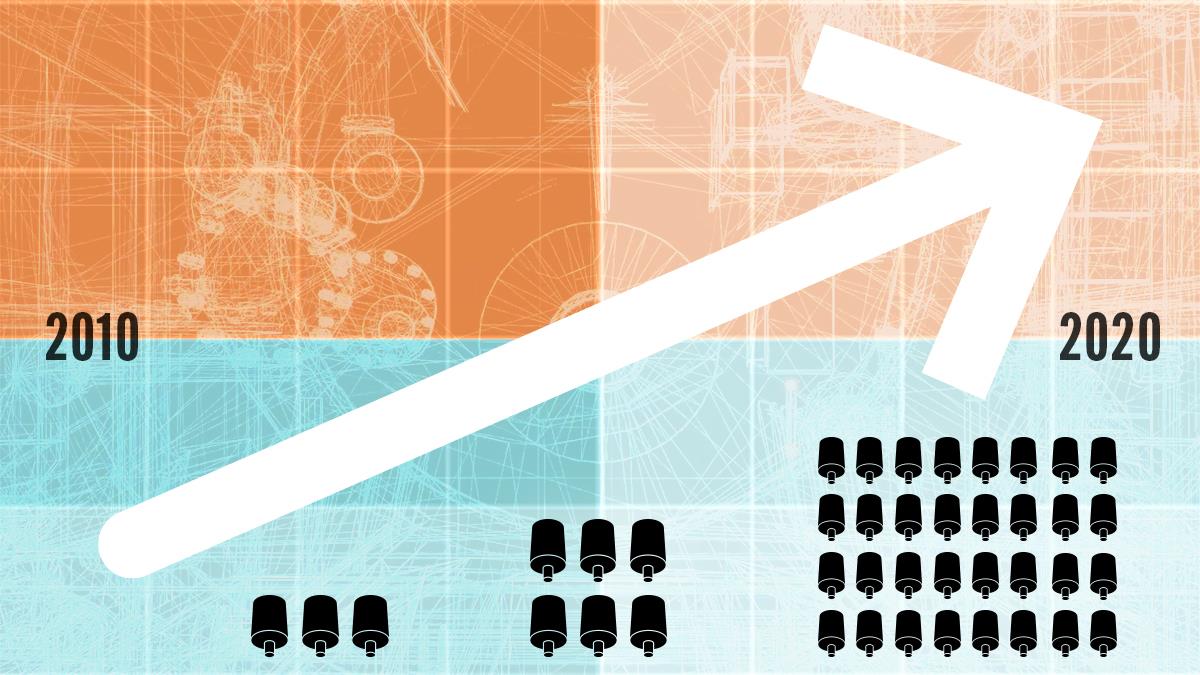

When I (Ed) first engaged with the condition monitoring ecosystem in 2008, tasked with developing a MEMS accelerometer roadmap capable of measuring vibration with sufficient resolution, only a handful of companies were exploring wireless vibration sensors. Of the three pioneers, just one had adopted MEMS sensor technology. Today, my database includes nearly 100 vendors offering almost 130 sensor models, with the majority featuring embedded MEMS sensors—a 22% annual growth rate.

What follows is an introduction to a three-part series of articles in which John and I will explore and clarify the challenges facing maintenance and reliability professionals considering wireless condition monitoring systems for their operations. We’ll describe the technology, contextualize it within traditional tools and practices, assess its potential to augment a PdM program, and ultimately offer guidance for assessing, choosing, and preparing to engage providers.

What Are Some Drivers and Inhibitors to Adoption?

Historically, the high cost of installing wired systems—requiring conduit, power, and data acquisition devices—limited automated data collection to protecting critical assets and turbomachinery. As wireless systems become more affordable, continuous monitoring becomes increasingly viable for a broader range of assets and applications.

The rapid expansion in vendors and solutions has been enabled by technological advancements such as low-power MEMS accelerometers, efficient IoT connectivity options, and AI-driven diagnostics. Condition monitoring instrumentation has also attracted significant investment. Publicly available investment data indicates that early-stage capital and private equity investors have poured over $400 million into this space. This does not include self-funded investments by some leading market players. Whether this trend represents "irrational exuberance" or a vast market opportunity—what one CEO has called a "land grab"—remains to be seen. History suggests a shakeout is inevitable as investors become impatient for returns and push companies to pivot or diversify in search of new growth opportunities.

Despite strong interest within the maintenance and reliability community, confusion persists about how to leverage this complex technology. A reliability professional confronted with complex feature sets, subscription-based business models, IT/OT integration requirements, and data management challenges may find themselves in unfamiliar territory. Even seasoned vibration analysts can struggle to interpret wireless sensor specifications, which differ significantly from those of legacy sensors and data collection instruments.

On the positive side, leading vendors report strong growth across industries. We estimate that the number of wireless sensors deployed for condition monitoring (primarily vibration) has reached or will soon surpass one million units. It is clear that this technology has secured a lasting place in maintenance toolkits, with many practitioners seeing tangible benefits. Judging by the level of professional investor engagement, there is still significant room for market expansion.

A recent survey of maintenance and reliability practitioners revealed one common reason for hesitation: "Our organization isn’t ready." Leading vendors report that some customers struggle to develop a technology assessment strategy—a structured approach for evaluating new tools based on organizational goals, resource capabilities, and operational constraints. Many maintenance veterans also note that manually collected route data remains the most cost-effective method per data point. This approach offers the added benefit of regular on-site inspections and reflects a preference for outsourced services. As a result, some question whether permanently installed vibration sensors deliver a strong enough return on investment.

Adoption also depends on the maturity of the PdM program and the motivations of stakeholders. Maintenance managers focused on daily firefighting may seek flexible data collection options to improve resource productivity. Reliability engineers may aim to boost asset uptime by expanding fault coverage through new technologies. C-suite executives often prioritize operational risk management and cost control, while IT departments may raise concerns over deployment-related issues such as data security and system integration.

Vendor messaging can further complicate adoption. As-a-service business models introduce OPEX vs. CAPEX considerations. Many value propositions are hard to differentiate from those of competitors or from results already achievable through mature PdM programs. New entrants, often backed by Silicon Valley or private equity investors, market aggressively with teaser deals on pilot deployments. Meanwhile, established PdM service providers, consulting firms, and industrial OEMs have incorporated wireless systems into their offerings—potentially reassuring customers through their expertise and track record.

All this noise can leave Reliability Managers feeling like proverbial deer in the headlights.

In this series, we aim to demystify the technology, provide useful context, and offer practical guidance. Whether you’re beginning to develop a technology adoption strategy or refining a mature PdM program, we hope to offer valuable insights.

What’s Ahead in This Article Series...

Part One: We’ll review the PdM framework as a foundation for adopting new technology or services, discussing topics like assessing ROI, reasons for underwhelming outcomes, and integrating condition monitoring into existing programs.

Part Two: We’ll examine key components of wireless condition monitoring technology, explore how sensor specifications have evolved from legacy systems, and highlight critical features and capabilities.

Part Three: We’ll present a structured approach to evaluating and engaging vendors. This includes curating today’s options, cutting through marketing claims, and providing insights into vendor positioning.